It’s not just any other solid wood table.

It’s solid wood, crafted with real joinery.

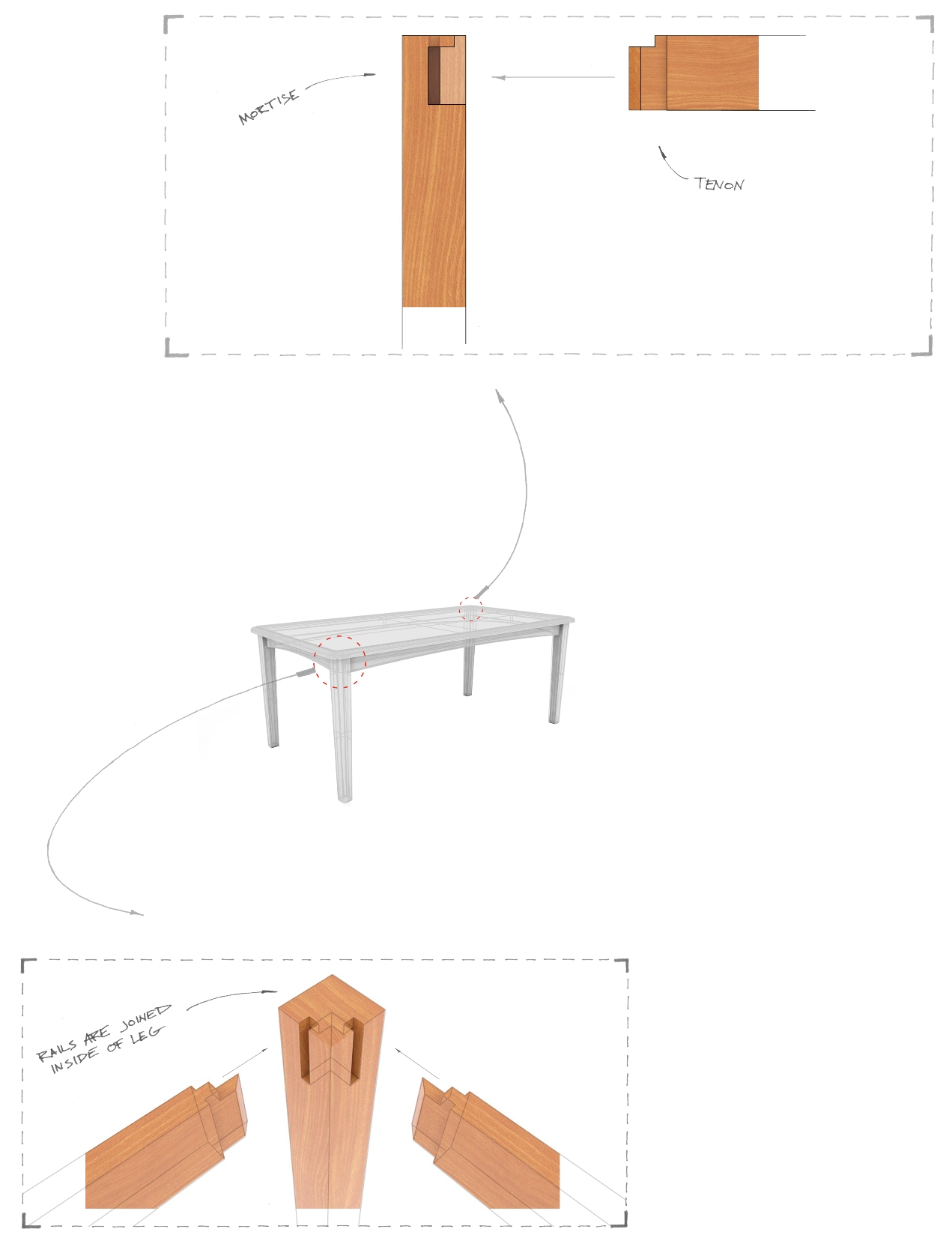

A high quality piece of furniture is comprised of a number of fundamental components; the most essential

of which is the structural system holding all of these things together, commonly known as the “joinery”. Our tables

are one of a kind in 2015 because they’re built with traditional mortise + tenon joinery; hybridized with modern

procedures +techniques to maintain efficiency, yet still hand crafted. Introduce yourself to the last table you will ever buy.

The history and components

of the mortise + tenon joint.

The mortise + tenon is the one of the most basic, yet most essential construction joints ever implemented. It’s basic parts

consist of a male component, called the tenon, and the female component, called the mortise. The joint is used to join a variety of materials

other than just wood, such as stone and metal, and has withstood the test of time. Wooden examples as old as seven thousand years have

been found, such as those at a Neolithic Hemudu site in Zheijang, China. Even the massive stone lintels of Stonehenge were mortised.

In the context of a typical four leg table, there are eight total mortises and eight corresponding tenons;

two per table leg. This is the strongest possible way to build a table, and in our opinion, the only responsible

way to build one. Anything less is not structurally capable of lasting for decades to come. Below you will

find a construction diagram of the way most of the tables you will find are constructed.

You may be wondering what actually holds this low quality construction together. That is achieved by simply butting the wood parts together, known as a butt

joint, and screwing a bracket of some sort into the corners. The bracket is typically made of some kind of metal or wood. Either way, the butt joint is the weakest of all of the

woodworking joints; over time it will loosen and eventually fail; no matter how well it’s executed. This method is inferior to a mortise + tenon joint.

Overall joint strength + accuracy.

The mortise and tenon joint is on it’s own is a very strong connection. After the joint is glued and assembled, it is never coming apart without exploding and failing

completely due to extreme abuse. There are however some stipulations which are crucial in the making of a strong mortise + tenon joint; mainly, the accuracy of the joint itself.

Our mortise + tenon joints are cut and fit with an extremely tight tolerance of 3-5/1000 of a inch, or [.003-.005″]. With research and testing, we have found this to be the optimal

joint tolerance specification. For those familiar with the metric system, that’s [.0254] mm! For comparison, the thickness of a US dollar bill is [.0043″], which is about

four times as thick. On top of this accuracy, we use a 100% waterproof glue with a breaking strength of 4,000 PSI. Lastly, we reinforce our mortise + tenon

joints with corner bracing for the strongest possible joint. Even if the the glue were to hypothetically fail, you would still have an intact connection.

Tabletop joinery, fastening

details, + wood movement.

The tabletop itself consists of multiple joints which usually go unseen. Most lumber typically comes in widths ranging from 4″-10″, so creating a 38″

wide tabletop actually consists of joining multiple boards together. These boards are squared and straightened and are glued edge to edge, which

creates a long grain to long grain glue joint. A properly glued seam is incredibly strong, and when put under an enormous amount of stress

you would find that the joint itself is actually stronger than the surrounding wood, which would yield before the joint itself would fail.

Lastly, the tabletop is joined to the base by using a system of edge glued cleats + slotted holes to account for wood movement. Because wood fibers absorb and release

moisture, wood is constantly in motion + constantly reacting to it’s environment. This movement is commonly known as expansion + contraction. Even the most dimensionally

stable species will move quite a bit, and all of this movement needs to be accounted for in order to retain the visual and structural integrity of the material.

![mortise and tenon plan diagram_lines [Converted]](http://www.receptivedesignshop.com/wp-content/uploads/2015/01/mortise-and-tenon-plan-diagram_resized.jpg)

![mortise and tenon plan diagram_lines_butt joint [Converted]](http://www.receptivedesignshop.com/wp-content/uploads/2015/01/mortise-and-tenon-plan-diagram_butt-joint_resized.jpg)

![mortise and tenon plan diagram_lines_corner-bracing_1 [Converted]](http://www.receptivedesignshop.com/wp-content/uploads/2015/01/mortise-and-tenon-plan-diagram_corner-bracing_resized.jpg)

Comments are closed.